Introduction to CIP in food and beverage manufacturing

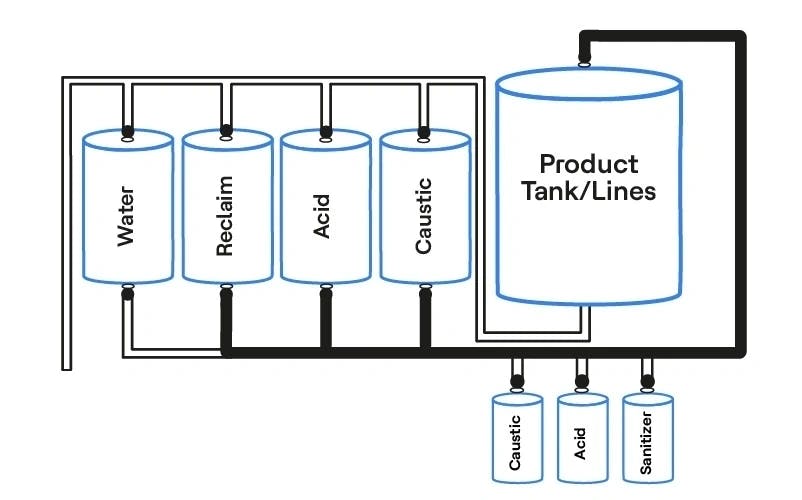

In the food and beverage industry, maintaining the highest levels of hygiene is essential to ensuring product safety and quality. The cleaning-in-place (CIP) process is a critical part of this, allowing manufacturers to clean the internal surfaces of equipment—such as tanks, pipelines, bottles and fillers—without disassembly. This system helps prevent contamination and maintains product integrity, especially when transitioning between different products, such as flavored beverages or dairy-based drinks.

However, CIP processes are resource-heavy, consuming significant amounts of water, chemicals and energy. Additionally, extended CIP cycles can lead to production downtime. This is why optimizing the CIP process is vital for improving productivity while adhering to environmental and safety standards.

Challenges in CIP optimization

Optimizing CIP in food and beverage manufacturing often faces challenges:

- Prolonged cleaning times reduce production uptime

- Excessive resource use, including water, chemicals and energy, adds operational costs

- Meeting regulatory standards and achieving hygiene benchmarks, such as ensuring the required temperature and chemical concentrations during cleaning, can be difficult without overextending the process

For instance, CIP must meet the stringent cleaning requirements in soda production lines like those in Coca-Cola and Pepsi. Transitioning between sugary sodas and flavored drinks requires thorough cleaning to avoid flavor cross-contamination and ensure safe production. These extended cleaning protocols can negatively impact production schedules and resource consumption.

AI-driven CIP optimization solutions

Food and beverage manufacturers are increasingly incorporating AI-driven solutions to optimize CIP processes. These tools can track data in real-time, identify inefficiencies and provide actionable recommendations for improvement.

By using predictive analytics, manufacturers can track cleaning phases, identify when cycles take longer than usual and adjust parameters to ensure optimized performance. These systems reduce unnecessary downtime and prevent resource wastage. For example, AI-based systems can provide alerts when cleaning cycles exceed typical durations, allowing for immediate intervention.

Key benefits of AI-driven optimization:

- Real-time anomaly detection to alert operators when cycles deviate from set thresholds

- Automated adjustments to cleaning schedules and resource use based on real-time data

- Predictive maintenance capabilities to ensure equipment health, reducing the likelihood of unexpected delays

Soda industry example: Optimizing CIP in Coca-Cola and Pepsi plants

Soda manufacturers like Coca-Cola Hellenic have optimized their CIP processes to reduce water, energy and chemical usage by adopting low-temperature, single-step cleaning technologies. This advancement has allowed Coca-Cola to shorten its cleaning cycles while maintaining strict hygiene standards, directly improving production uptime.

In a particular use case, Coca-Cola Hellenic observed that the pre-rinse phase was extended due to inconsistent water pressure, leading to longer CIP durations. After adjusting the water pressure, the company was able to reduce CIP times by 12% increasing overall production efficiency (beveragedaily.com).

Similarly, Pepsi has implemented volume-controlled CIP systems, optimizing cleaning phases while recovering and reusing cleaning agents like caustic soda and phosphoric acid. These optimizations have resulted in significant cost reductions and improved operational flexibility.

Root cause analysis for CIP failures and extended cycles

In some cases, CIP processes may not meet quality standards, leading to failed cleaning attempts. A detailed root cause analysis can help identify and resolve these issues. For example, manufacturers have reported CIP cycles extending beyond expected durations, which can significantly affect production schedules.

In a real-world scenario, the last water rinse phase of a CIP process was observed to extend well beyond its standard duration. AI-driven analysis determined that the final rinse phase was consuming more time due to insufficient water pressure, resulting in longer cleaning cycles. After addressing this, manufacturers were able to reduce the duration of the entire CIP process, reducing water and energy consumption.

In another scenario, troubleshooting was required when CIP processes failed to meet cleaning specifications. By analyzing the data, operators found that the temperature inside the CIP vessel had dropped below the required 90°C, preventing successful cleaning. Cross-referencing data from other systems showed a correlation with increased steam usage by a nearby spray dryer that was depleting the energy needed to maintain the CIP temperature. By resolving the steam allocation issue, the company could improve CIP effectiveness and increase production output.

Operators can overlay different cleaning cycles to compare their durations using dashboards and trend monitoring tools, identifying deviations from the ideal CIP process. They can then set up notifications to alert them when a CIP cycle exceeds the set threshold, ensuring immediate corrective action.

Technical enhancements in CIP monitoring and control

Advanced monitoring systems allow manufacturers to:

- Track CIP phases and identify when specific phases take longer than expected.

- Perform value-based searches to filter events based on duration or specific tags (e.g., temperature or flow).

- Set up automated email alerts to notify engineers when cleaning cycle deviations occur, allowing for faster resolution.

- Utilize correlation analysis to find upstream events affecting CIP efficiency, such as temperature drops or increased steam consumption, which could be caused by unrelated processes drawing on the same energy resources.

By performing these root cause analyses, manufacturers can significantly reduce CIP cycle duration and prevent recurring failures. For example, resolving a steam consumption issue in the spray dryer section of a plant led to a 1-2% increase in production after successful CIP implementation.

Conclusion

Optimizing the cleaning-in-place (CIP) process is crucial for improving production efficiency in the food and beverage industry, especially for soda manufacturers like Coca-Cola and Pepsi. By leveraging AI-driven monitoring tools and performing detailed root cause analyses, manufacturers can reduce cycle times, minimize resource use, and improve overall operational efficiency.

Through real-time data, anomaly detection and automated adjustments, food and beverage companies can optimize their CIP processes to ensure they meet hygiene standards while also improving sustainability and production output. The reduction in water and energy consumption, as seen in the 60% decrease in ultra-pure water usage during extended CIP phases, illustrates the potential benefits of a well-optimized cleaning process.

In summary, CIP optimization increases production capacity and contributes to sustainability goals and cost savings, giving food and beverage manufacturers a competitive edge in a rapidly evolving industry.