GenAI is revolutionizing manufacturing practices by enhancing product design and optimizing production processes. Unlike traditional methods that rely heavily on human intuition and manual calculations, GenAI leverages advanced algorithms to explore various design possibilities based on specific parameters such as material constraints and performance requirements. This capability allows manufacturers to create components that are not only more efficient and cost-effective but also innovative in terms of design and functionality.

Additionally, GenAI plays a crucial role in predictive maintenance by analyzing equipment data to anticipate potential failures, thus enabling proactive maintenance scheduling. This minimizes downtime, extends the lifespan of machinery and ultimately reduces operational costs, resulting in a more streamlined and efficient production process.

Large Language Models (LLMs) are transforming manufacturing by improving communication, decision-making and problem-solving capabilities across the supply chain. LLMs can process and interpret vast amounts of unstructured data from various sources, including technical manuals, maintenance logs and customer feedback, providing actionable insights and recommendations. They assist technicians by generating detailed instructions for complex repairs, interpreting alert notifications and narrowing down potential issues based on historical data.

Furthermore, LLMs enhance collaboration across global teams by offering multilingual support and facilitating knowledge sharing through natural language processing. This leads to improved workforce productivity and more efficient operations, enabling manufacturers to respond more effectively to challenges and drive innovation across the manufacturing sector.

Enhanced product design and development

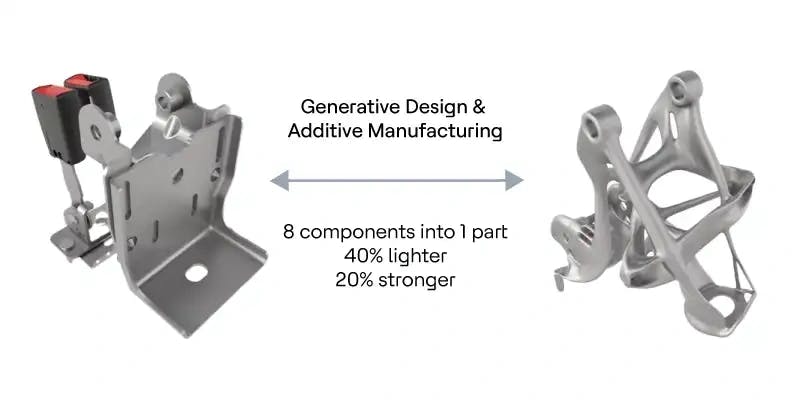

GenAI is revolutionizing product design by enabling manufacturers to create optimized and innovative solutions that were previously beyond reach. Unlike traditional design methods that often rely on human intuition and experience, which can limit creativity and efficiency, GenAI employs advanced algorithms to explore a multitude of design possibilities. These algorithms consider various parameters, such as material constraints, performance requirements and cost limitations, to generate thousands of alternative designs. This process results in solutions that are often more efficient, lightweight and cost-effective than those produced by conventional means. Large Language Models (LLMs) further enhance this process by providing designers with insights derived from technical manuals and historical design data, enabling more informed decision-making and design iterations.

A notable example is General Motors (GM), which has used GenAI to enhance vehicle design. By partnering with Autodesk, GM utilized generative design software to develop lightweight and structurally optimized components. This approach allowed GM to quickly explore a wide range of design possibilities, leading to components that are 40% lighter and 20% stronger than traditional parts. GM and Autodesk Team Up

According to a report by McKinsey, companies implementing AI in product design can achieve a 10% to 30% improvement in engineering efficiency, highlighting the transformative potential of this technology.

Process optimization and automation

GenAI plays a critical role in optimizing manufacturing processes by examining large volumes of data to identify inefficiencies and potential improvements. AI-driven insights enable manufacturers to streamline operations, reduce waste and enhance productivity. For instance, AI algorithms can monitor production lines in real time, pinpointing bottlenecks, predicting equipment failures and recommending adjustments to optimize throughput. LLMs contribute by analyzing maintenance logs and operational reports, providing actionable insights that help refine processes and improve efficiency. These models facilitate better communication across teams by synthesizing complex information into understandable formats, ensuring that technicians and managers can implement improvements effectively.

A prime example is Siemens (Siemens Manufacturing GenAI), which has implemented GenAI to optimize its manufacturing processes, particularly in its electronics and automation division. By using AI, Siemens has significantly improved production efficiency and quality. The AI system analyzes data from production lines to fine-tune machine settings and predict maintenance needs, resulting in reduced downtime and increased output. A study by Deloitte found that 93% of companies believe AI will be a key driver of growth and innovation in their manufacturing operations, underscoring its importance in modern manufacturing.

Quality control and predictive maintenance

Ensuring product quality is a top priority in manufacturing, and GenAI is making substantial advances in this area. AI-powered quality control systems can scrutinize images and sensor data to detect defects and anomalies in real time, allowing manufacturers to address quality issues early in the production process. This capability helps reduce scrap rates, improve yields and deliver higher-quality products to customers. LLMs play a pivotal role in interpreting quality control data and generating reports that highlight potential problem areas, making it easier for quality assurance teams to target their efforts effectively.

In addition to quality control, GenAI is transforming maintenance and troubleshooting tasks in manufacturing environments by providing technicians with powerful tools and insights that enhance efficiency and accuracy. AI-driven systems can offer technicians guided maintenance procedures by analyzing historical data and real-time equipment conditions to deliver dynamic, context-aware instructions. For instance, Siemens uses AI to guide technicians through complex repair tasks with tailored instructions based on previous repairs.

Additionally, GenAI enables predictive maintenance by analyzing sensor data to forecast potential failures. LLMs support this process by extracting relevant information from extensive technical documentation and delivering precise maintenance steps, improving the speed and accuracy of repairs.

GenAI also aids in optimizing resource allocation by predicting maintenance needs and providing actionable insights. This ensures that spare parts and labor are available when needed, reducing delays and improving efficiency. For example, Bosch utilizes AI to forecast spare parts demand based on predictive maintenance insights, effectively managing inventory to support technicians. According to IDC, by 2024, 60% of G2000 manufacturers will use AI platforms to drive productivity improvements of at least 20%.

Customization and mass personalization

The demand for personalized products is growing, and GenAI is transforming manufacturing by enabling mass customization across industries. This technology allows companies to analyze vast customer data, including preferences, past purchases and physical measurements, to create tailored product designs and configurations. This ability to personalize enhances customer satisfaction and provides a competitive advantage. LLMs enhance this capability by processing customer feedback and market trends to suggest new features or customizations, ensuring that products remain aligned with consumer desires.

Adidas has harnessed GenAI in the fashion industry to transform its shoe design process. The company uses AI to analyze foot scans and customer preferences, enabling it to produce personalized shoe designs that offer optimal fit and performance. Adidas' Futurecraft 4D shoes, which utilize 3D printing technology and AI insights to create midsoles tailored to the wearer's needs, exemplify this approach. By offering customized products, Adidas not only enhances comfort and performance but also differentiates itself in the competitive footwear market.

GenAI is also making waves in the automotive industry, where it allows manufacturers to offer customized vehicle features and configurations. BMW uses GenAI to support its BMW Individual program, enabling customers to personalize their vehicles with bespoke features such as custom paint colors, unique interiors and exclusive materials. AI algorithms analyze customer data and preferences to suggest personalized options, enhancing the ownership experience. This approach not only satisfies consumer desires for uniqueness but also strengthens brand loyalty by offering truly personalized products. A study found that 70% of consumers express interest in purchasing personalized products, highlighting the growing demand for customization.

Conclusion

GenAI, complemented by the capabilities of Large Language Models, is reshaping the manufacturing landscape by driving innovation, efficiency and quality across the industry. AI technologies are revolutionizing how manufacturers operate and compete, from enhancing product design and process optimization to predictive maintenance and mass personalization. As GenAI and LLMs continue to advance, their impact on manufacturing will only increase, allowing companies to remain agile, responsive and successful in a rapidly changing global market. Embracing these technologies is not merely a technological upgrade but a strategic imperative for manufacturers seeking to thrive in the digital age.