Introduction

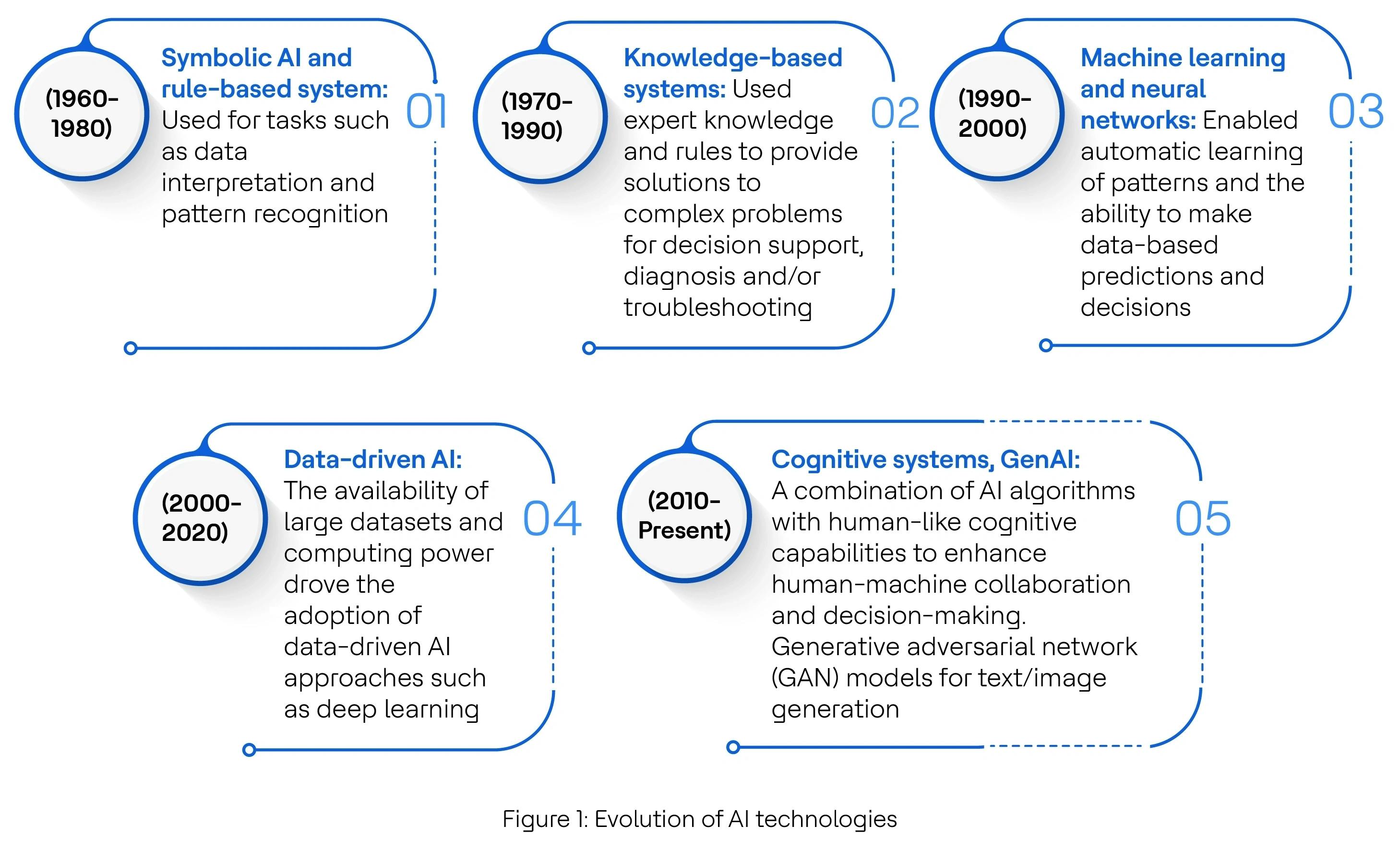

AI is reshaping nearly every industry, and A&D is no exception. AI adoption has enabled significant advancements in both commercial aerospace and defense, with applications ranging from predictive analytics to autonomous systems and decision support. As AI evolves, the industry will further leverage its potential to drive innovation, improve operational efficiency and enhance safety and security. The figure below shows the evolution of AI from rule-based expert systems to the cognitive systems and GenAI technologies in use today.

By harnessing the power of AI, A&D companies are unlocking new possibilities through enterprise transformation across various business functions and processes, resulting in cost reduction and improved efficiency. The availability of enormous amounts of data and advances in computing power have propelled the adoption of the data-driven AI approach, which has been instrumental throughout the A&D product lifecycle. A few processes that have been especially impacted include engineering design, additive manufacturing, supply chain optimization, contracts management, simulation and predictive maintenance. Additionally, GenAI has opened new possibilities such as creating synthetic data to train machine-learning models, generating design iterations to optimize product design and accelerating the process of creating digital twins.

Prominent AI applications and Generative AI use cases

In this section, we’ll look at domains where AI is facilitating A&D enterprise transformation and instances where GenAI can enhance existing capabilities to create value.

- Product development: AI algorithms accelerate prototyping and the design iteration process to generate optimal aircraft designs by training models on existing product specifications and datasets. They also expedite the validation and testing of design concepts, reducing the time and costs associated with traditional prototyping methods and accelerating product development for faster time to market. We are witnessing the introduction of next-generation AI software solutions in the market, facilitating designers and engineers to swiftly transform product concepts into computer- aided design models. This capability accelerates product modeling significantly, expediting the engineering process. For example, Airbus utilized generative design tools with Autodesk to reengineer several parts of its planes, such as partitions for aircraft cabins and vertical stabilizers. This led to enhanced fuel efficiency and reduced environmental impact and eventually to manufacturing multiple units at a considerably lower cost. In another case, HCLTech helped a global automotive company identify and optimize designs using our no-code AI software, which aids designers in generating new designs and enables live prediction of how designs would perform. The terms generative design and generative AI have often been used interchangeably, however they are not the same. While generative design can optimize and iterate through various design variations using AI/ML models, generative AI can help accelerate that design process workflow.

- Predictive maintenance and engine inspection: Several aeroengine manufacturers and airlines use AI to analyze sensor data and historical maintenance records to predict engine failures, optimize maintenance schedules and reduce downtime, thus improving overall equipment reliability. For an aircraft manufacturer, HCLTech deployed AI technologies for survival analysis, hazard protection and predictive maintenance to reduce cost. We’re also seeing increasing use of AI in visual engine inspection. For example, Pratt & Whitney, in collaboration with Awiros, launched an AI-powered engine monitoring tool that automates engine inspections and provides maintenance personnel with real-time information on parts availability. Augmenting existing predictive maintenance capabilities with GenAI could help identify scenarios that may not result from historical data and provide detailed insights on required component replacements. Similar use cases could be observed in defense industry for aircraft weapons system maintenance. For example, the US Air Force uses the Predictive Analytics and Decision Assistant (PANDA) tool, an integrated AI and machine-learning tool, for predictive maintenance to increase the operational reliability of weapons systems. The tool leverages C3 AI’s GenAI capabilities to retrieve information from disparate data sources and interpret maintenance text narratives of previous maintenance actions to determine the next course of action. In addition to engine inspection, GenAI capabilities are being adopted for visual aircraft inspection. For example, Boeing is training machine-learning algorithms with synthetic images to enable efficient aircraft inspection using augmented reality.

- Supply chain and procurement: AI models can optimize supply chain strategies for A&D companies by analyzing demand fluctuations, production schedules and procurement activities. This enables them to mitigate risks by striking the right balance between inventory levels and costs. Another AI use case is generating supplier recommendations based on factors such as pricing, quality and capacity requirements. Moreover, GenAI can streamline supplier selection process further by analyzing performance data and other criteria. A&D companies typically also face challenges in the contract reporting process, which can be time- consuming, costly and error-prone, increasing deployment times, compliance and financial risk. Some of these challenges can be addressed with AI, which can automate the process. For example, HCLTech and Evisort’s AI-powered contract analytics solution can be seamlessly integrated with SAP Ariba procurement solutions to turn contracts into searchable data without manual data entry. Also, Evisort AI Labs has recently introduced a GenAI solution that drafts contracts, making contracting faster and more efficient.

Gen AI to empower and accelerate the A&D industry transformation

- Digital Engineering

- Accelerate Generative design process of aircraft components/parts to evaluate numerous design variations quickly

- Automation of engineering design process, allowing designers to focus on complex areas of work

- Speed up the testing and validation process through virtual prototyping and simulation

- Creation of digital twins to predict aircraft engine performance

- Digital Manufacturing

- Visual inspection systems to detect product defects and ensure quality during component manufacturing

- Automate and optimize the process of data curation and reconciliation from manufacturing execution systems

- Production planning to minimize bottlenecks and optimize production efficiency

- Assess multiple production scenarios to evaluate the impact and recommend the best course of action

- Digital Aftermarket

- Predict component failures by analyzing historical maintenance data, reducing unplanned downtime

- Interpretation of maintenance manuals and airworthiness directives for specific aircraft models

- Automatic generation of maintenance documents, digital records of aircraft/engine health and inspection repots

- Automation of parts ordering for preventive maintenance

- Field Worker Safety: Generate Safety Guidelines, Create realistic simulations

- Digital Supply Chain

- Supply chain visibility, enabling operators to quickly access information about components and parts, vendors, sales orders and inventory

- Suppler relationship management: Analyze supplier performance data to optimize vendor selection

- Contract lifecycle management: Review and analyze contract information, simplifying and summarizing the complex contract clauses through conversational AI capability

- Digital Enterprise

- Get insights and data from ERP and PLM systems through natural language queries

- Customer service and engagement: Provide personalized communication, case management and targeted marketing

- Sentiment analytics: Employee and customer sentiment analysis to optimize customer journey

- Virtual assistant to assist call center agents

- Employee experience: Customized L&D and personalized engagement

Scaling AI capabilities with cloud

Cloud technologies develop and expand AI applications for the A&D industry, and cloud platforms such as AWS, Microsoft Azure and Google Cloud have many benefits for GenAI applications:

- Big data storage: GenAI models for product development or predictive maintenance applications often rely on vast amounts of product or sensor data for training. Cloud platforms offer secure and scalable data storage solutions, enabling companies to store and manage large datasets effectively, which ensures seamless integration with GenAI workflows. For example, Boeing is migrating applications from on-prem data centers to the AWS cloud to strengthen engineering and manufacturing processes.

- Cost savings and scaling AI infrastructure: Leveraging cloud resources eliminates the need for upfront capital investments, reducing operational costs and providing the necessary infrastructure and computing power to scale AI applications. These platforms provide prebuilt AI frameworks, libraries and APIs, making it easier for A&D companies to implement GenAI solutions. For example, GA Telesis uses Google Cloud’s Vertex AI platform to transform their sales and service processes for supplying parts to major global air carriers.

- Collaborative workflows: GenAI projects often involve interdisciplinary teams, including designers, engineers and data scientists. Cloud platforms enable efficient collaboration, data sharing and version control, fostering a more streamlined and productive workflow.

HCLTech’s approach to GenAI

HCLTech advises, curates and orchestrates technologies from market-leading partners and innovators. Together, we provide scalable, fully integrated AI solutions that deliver next-level results. We use large language models (LLMs) such as GPT, Llama, Gemini and others, leveraging our partnerships with leading hyperscalers such as Microsoft, GCP and AWS to develop and deploy GenAI capabilities for our clients to enhance employee productivity, streamline IT operations, accelerate application development and optimize business processes.

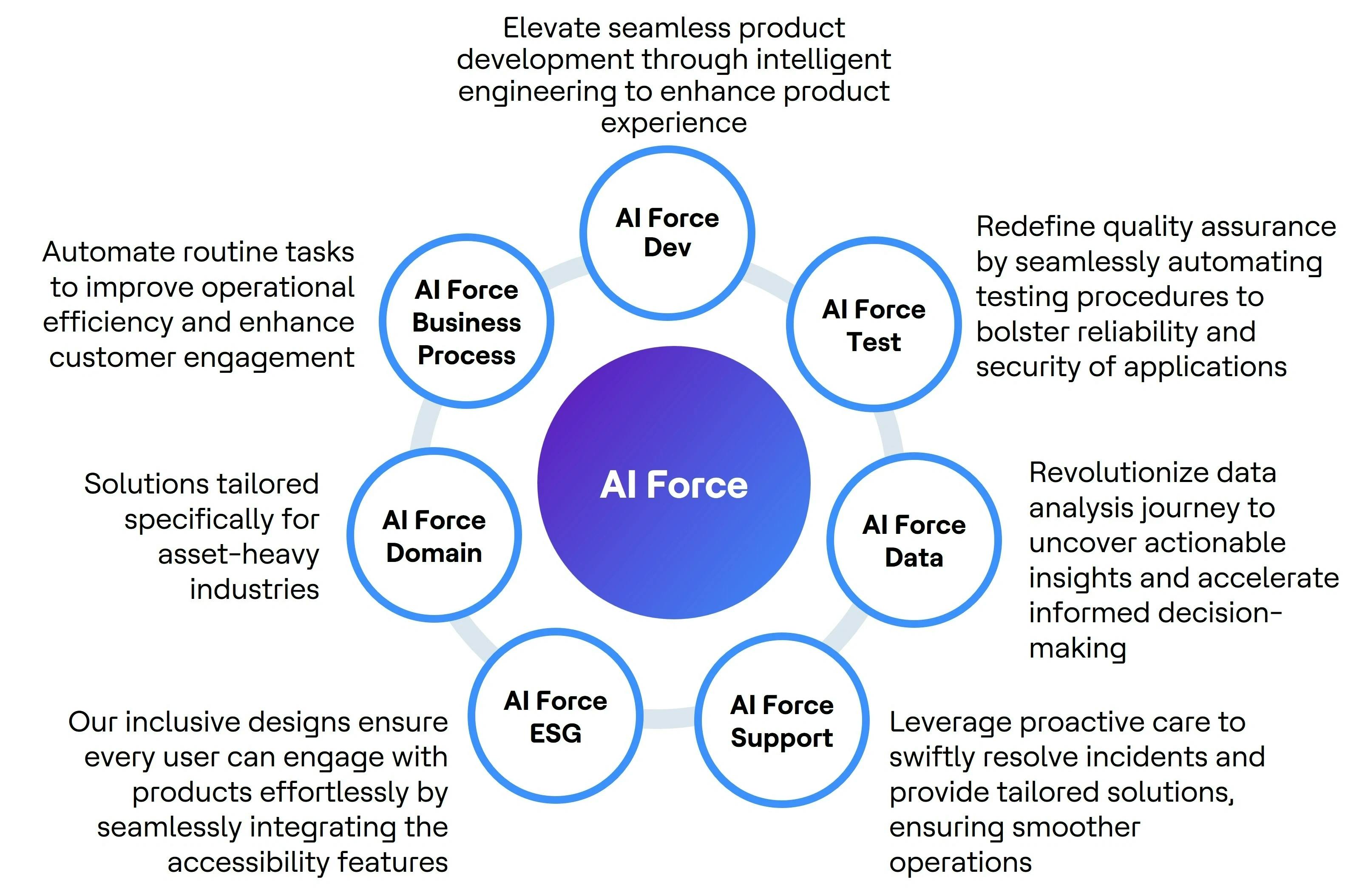

We’re excited to announce our full-stack GenAI solution offerings as part of the AI Force platform. These are designed to help clients achieve business transformation across many functions. Our solutions cover the entire enterprise business process landscape, from product development, quality assurance, software testing, manufacturing and engineering to other functions such as customer service, procurement, finance, sales and marketing.

AI Force is a full stack set of solution platforms tailored with GenAI models, tools and technologies to meet unique business requirements in transforming, modernizing and redefining various business functions and the workplace landscape, paving the way for a more efficient future.

Figure 2: HCLTech AI Force platform

Figure 2: HCLTech AI Force platform

Use case on analysis of maintenance service bulletins

A service bulletin (SB) is an airworthiness-approved document created by an aircraft manufacturer to implement a change to the design type of an aircraft or a report on an inspection of a delivered aircraft to maintain its safety level or improve its operation. The primary users of SBs are aircraft maintenance personnel, including mechanics, engineers and technicians as well as aircraft operators and regulatory authorities. SBs are crucial for ensuring the continued airworthiness of aircraft and compliance with regulatory requirements.

Solution/Offerings:

- GenAI can parse and interpret the technical content of SBs, providing simplified summaries, key points or actionable insights in plain language to aid comprehension

- Highlight the most critical updates relevant to a particular aircraft fleet/model/part or maintenance operation

- Extract the instructions/objectives and tasks associated with a particular SB to comply with the SB

Benefits:

- Improved efficiency: Automating the process of sorting, prioritizing and summarizing SBs, saving time and effort for maintenance personnel — by streamlining information consumption, personnel can focus more on critical tasks and reduce administrative overhead

- Increased relevance: Receive information tailored to specific aircraft fleets or parts

Business Needs:

- Monitor and track SBs to ensure that aircraft remain in compliance with the latest maintenance requirements and safety standards.

- The process of consuming SBs involves manual reading, interpretation and dissemination of information that can lead to potential errors and delays.

- Not all SBs may be relevant to a specific aircraft fleet or maintenance operation, requiring personnel to go through large volumes of information.

Key Features

- Automatic updates and alerts

Integrate with existing maintenance management systems (e.g., HCLTech iMRO) - On-time compliance

Ensuring on-time compliance with SBs or airworthiness directives - Recommendation

Actions tailored to specific roles, expertise levels and aircraft fleets

Conclusion

As we've explored, GenAI applications span critical areas such as digital engineering, manufacturing, supply chain management, aftermarket services and enterprise operations. Collectively, these applications underscore GenAI’s transformative potential in revolutionizing every aspect of the A&D industry value chain.

By embracing Generative AI, organizations can unlock new levels of innovation, efficiency and competitiveness. The application of GenAI technologies will lead to more sustainable and efficient products and services for A&D companies, increasing performance and enhancing customer experience.

Our expertise and full-stack generative AI capabilities can help A&D companies navigate the complexities of generative AI adoption with confidence, realize tangible positive business outcomes and become leaders at the forefront of the industry’s evolution.

References

- https://www.eurekamagazine.co.uk/content/technology/airbus-has-moved-from-generatively-designing-components-to-the-factories-in-which-they-are-built

- https://www.hfsresearch.com/research/hcltech-drives-business-ops-and-experience-with-live-genai/

- https://technologymagazine.com/ai-and-machine-learning/next-generation-unified-ai-and-cloud-from-HCL-technologies

- https://www.aviationtoday.com/2023/06/23/pratt-whitney-launch-percept-an-ai-powered-automatic-engine-inspection-system/

- https://defensescoop.com/2023/05/10/air-force-selects-ai-enabled-predictive-maintenance-program-as-system-of-record/

- https://c3.ai/improving-us-air-force-mission-capability-with-ai/

- https://www.evisort.com/blog/evisort-ai-labs-announces-invention-of-generative-ai-for-contracts

- https://cloud-computing.tmcnet.com/breaking-news/articles/452099-boeing-migrate-more-applications-aws.htm

- https://www.gatelesis.com/leading-global-airline-supplier-ga-telesis-integrates-google-clouds-generative-ai-technology/