Introduction

In today's global landscape, large corporations have manufacturing plants operating with large and complicated supply chain networks in different locations. In many cases, manufacturing plants started as silo plants. Then, they expanded in numbers as corporations expanded, at times acquired by other corporations, which led to diverse technologies and solutions in different plants of the same corporation. These challenges, coupled with technological advancements and regulatory compliance, shape the complex and dynamic landscape of the manufacturing sector.

In this landscape, manufacturers face an uphill task of improving efficiency, capacity, business agility, compliance and quality while balancing cost-effective production and adhering to stringent standards.

The manufacturers’ search for excellence

To address the above challenges, manufacturers seek solutions that can:

- Provide visibility into manufacturing operations

- Identify risks

- Identify areas of improvement

- Optimize operations

- Automate decision-making at various levels

- Provide insights for decision-making

- Provide insights on possible outcomes of various decisions with an optimal skilled workforce

Manufacturers aspire to achieve these with cost-effective solutions that can be implemented at one site and scale out quickly to various plants and with centralized manufacturing operations.

Harnessing digital power: Smart technologies to supercharge manufacturing processes

Manufacturers must adapt, innovate and transform to thrive in this ever-evolving environment. Digital transformation in the manufacturing industry has crossed the early adopter phase. For manufacturing domain organizations, it is also necessary to evolve to stay competitive in a rapidly changing world. Digital technologies enable accelerating transformation in manufacturing, leading to more innovative, efficient and responsive production ecosystems that can adapt to new challenges and opportunities with unprecedented agility.

The latest advancements in AI, including GenAI, are either redefining or transforming what is possible in design, production and quality control. AI algorithms can help optimize production lines in real-time, machine vision technologies can help identify product quality issues and GenAI can be leveraged in various use-cases like intelligent chatbots for improving productivity, automate summarizations, audit processes and in some cases, propose new product designs and improvements. Knowledge graphs are essential in connecting data points to give a comprehensive view of processes, assets and relationships, enabling more strategic planning and operational efficiency.

Digital twin is a digital representation of a physical system that is dynamically updated with data to reflect the actual state and behavior of the system. Clients can drive business outcomes by leveraging digital twin in various ways:

- Real-time monitoring, root cause analysis and training purposes

- Operations planning and predictive maintenance

- They perform What-If analysis and provide prescriptive guidance on actions

- Using digital twins can help accelerate innovation and significantly reduce costs and downtime

Data platforms help aggregate and analyze vast amounts of data from various IT and OT systems. They are the base for implementing decision systems and AI-powered applications.

Lastly, the cloud is the backbone for transformation, offering scalable, cost-effective resources and facilitating collaboration across global teams. It is the enabler for all other digital technologies, such as AI, GenAI, digital twins, knowledge graphs, data platforms, etc.

Together, these technologies are accelerating digital transformation in manufacturing, leading to more intelligent, efficient and responsive production ecosystems that can adapt to new challenges and opportunities with unprecedented agility.

HCLTech's M360 manufacturing suite: Accelerator for building smart manufacturing applications

HCLTech's M360 helps manufacturers on their digital transformation journey by accelerating the implementation of innovative manufacturing applications. The solution suite integrates data from multiple data sources. It utilizes advanced AI techniques and digital twins to provide end-to-end visibility, data-driven decision-making and a recommendations framework to optimize the process and drive operational excellence.

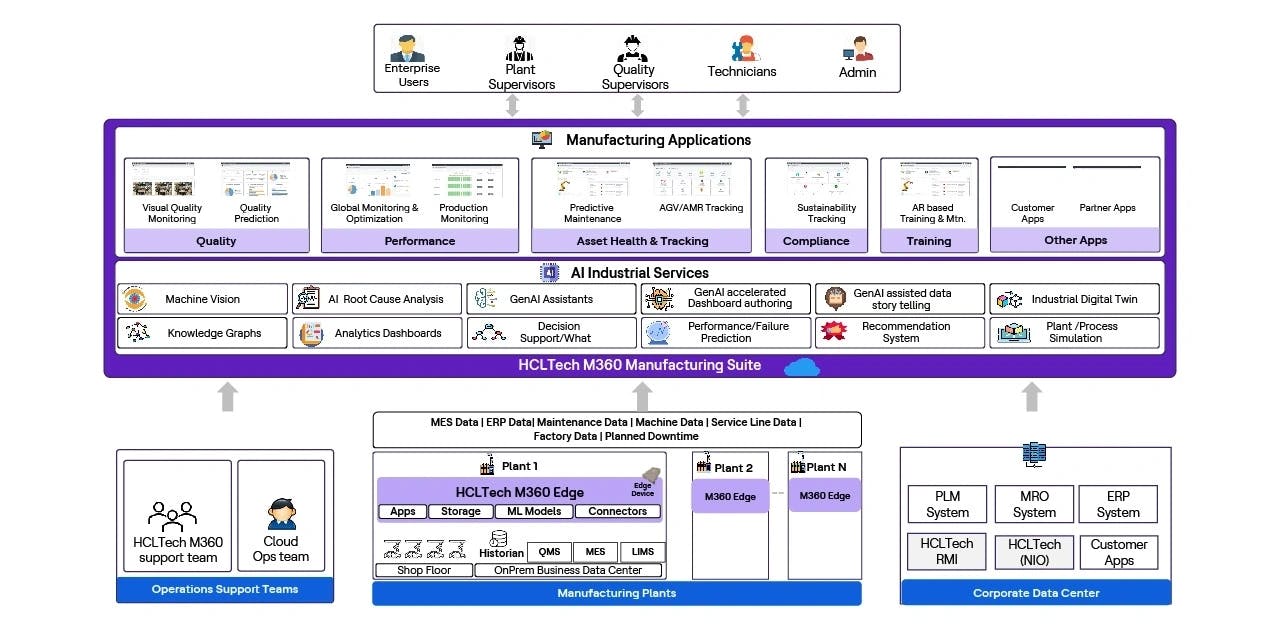

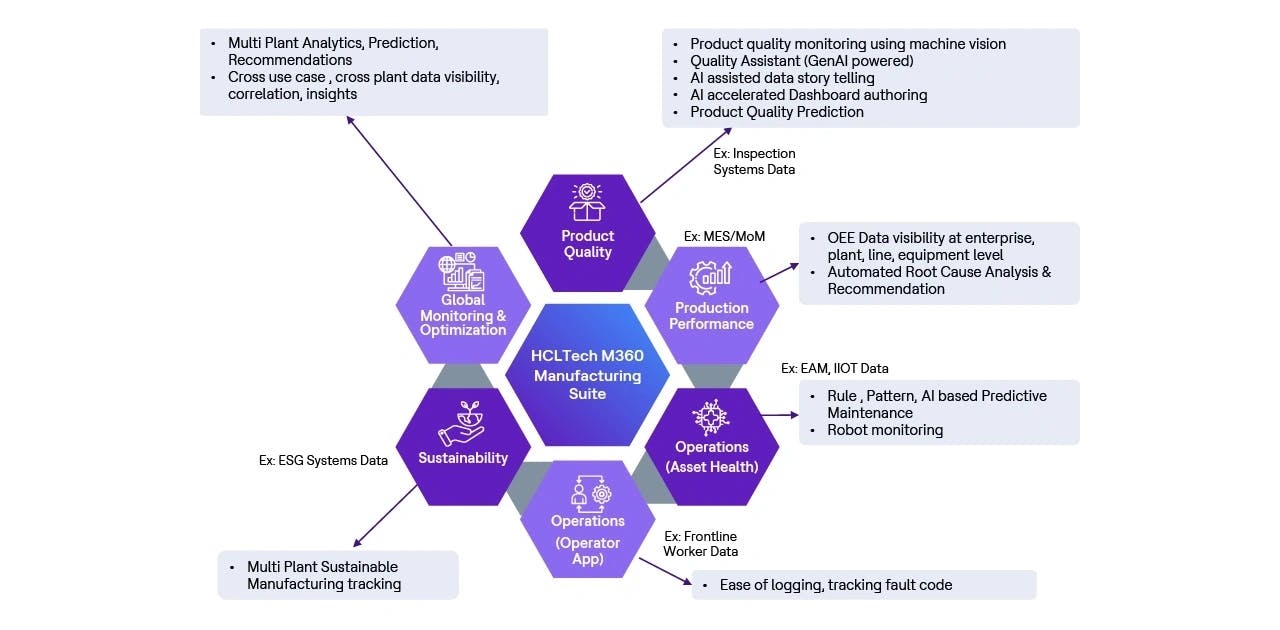

Figure 1 – HCLTech M360 Manufacturing Suite

- M360 industrial AI services is a customized service for industrial use cases that leverage AI, including GenAI, digital twins, knowledge graphs, etc.

- M360 industrial AI services helps analyze, simulate, predict and recommend production and equipment scenarios

- Manufacturing applications leverage Industrial AI Services to deliver various use cases like quality and performance monitoring, asset health and tracking etc. (as shown in Figure 1)

- M360 Edge operates in the plant as a ‘Smart AI Edge module’ to deliver intelligence and decision-making support at the plant level; it is ideal for use cases that require real-time action or response

- M360 Smart AI Edge can run deep-learning AI models on plant premises to identify anomalies in manufacturing processes, equipment health and products and alert users immediately

- Context-aware GenAI capability is integrated into M360 manufacturing applications

- GenAI-powered components like AI-powered quality assistants, AI-assisted data storytelling, AI accelerated dashboard authoring, AI-powered maintenance assistants and production simulation are part of M360 industrial AI services

M360 economic impact

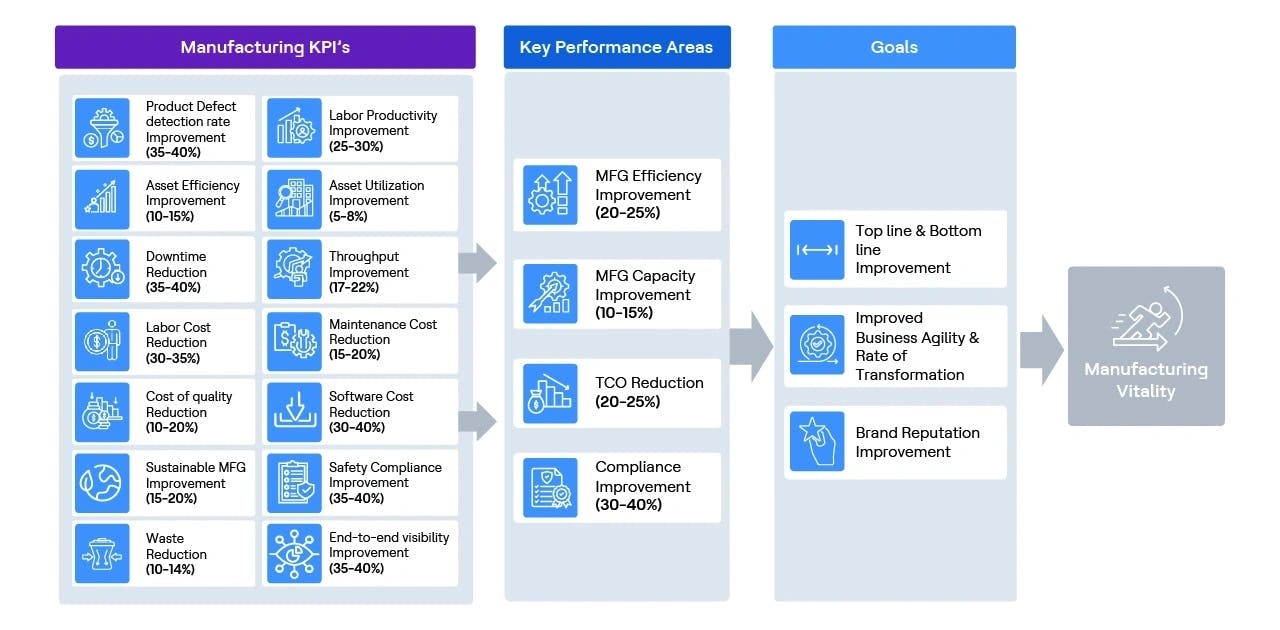

M360 suite uses manufacturing KPIs as business measures to reveal new opportunities for growth and profitability. Different use cases adopted in the digital transformation journey impact different manufacturing KPIs.

M360 offers a flexible model for incremental use case adoption. Figure 2 describes the impact of various manufacturing KPIs and their cascading impact on key performance areas and corporation goals.

Example: Manufacturer implements one of the M360 modules, i.e., visual product quality monitoring, to detect product quality issues using machine vision instead of manual quality checks.

This automation will impact manufacturing KPIs, such as defect detection rate, labor productivity, throughput and cost reduction. In addition, integrated GenAI-based quality assistance helps improve labor productivity. Improvement in all these manufacturing KPIs will help improve manufacturing efficiency.

Figure 2 – Unlocking the path to Manufacturing KPI improvement

Use case spotlight: Improve product quality labor productivity using machine vision, deep learning and GenAI

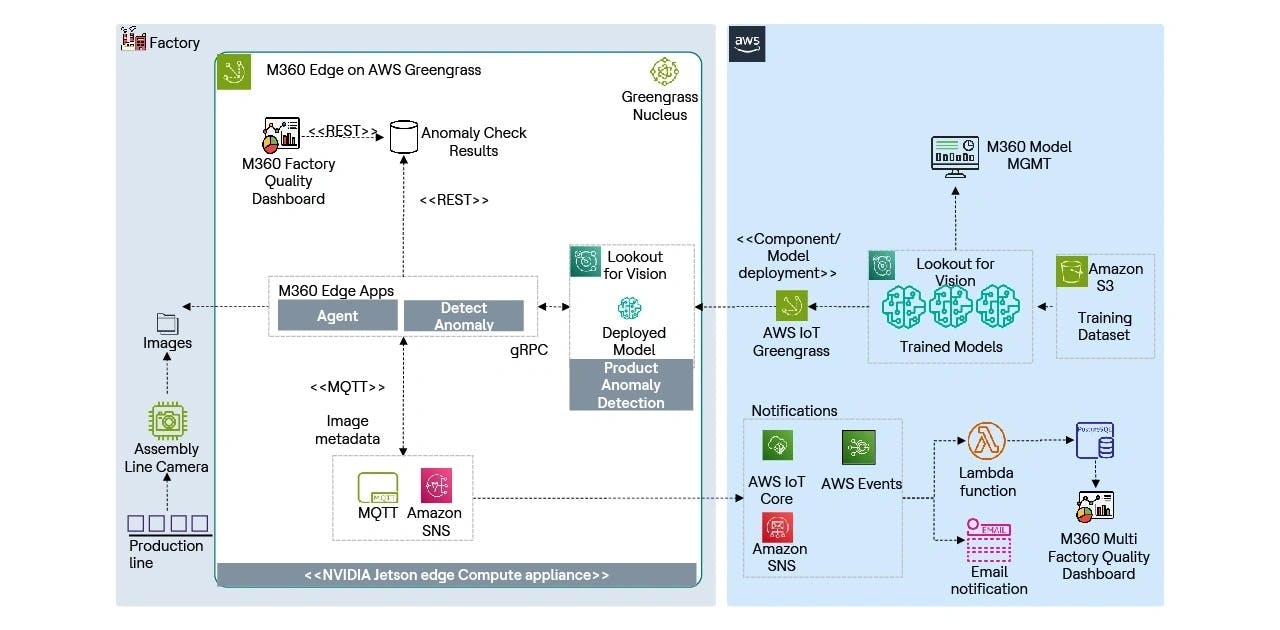

The HCLTech M360 visual product quality monitoring module leverages various AWS services and offerings to deliver a machine vision-based product quality monitoring solution.

- Amazon Lookout for vision is an ML service that uses computer vision to spot defects in manufactured products. As a fully managed service, it accelerates model training and reduces time to market for new capabilities

- AWS IoT Greengrass makes it easy to bring intelligence to edge devices. M360 Smart Edge solution leverages AWS IoT Greengrass to run machine learning, application and data processing components at the edge

- AWS IoT Core is a managed cloud platform that lets connected devices easily and securely interact with cloud applications

Figure 3 – M360 Product Visual Quality Monitoring Architecture

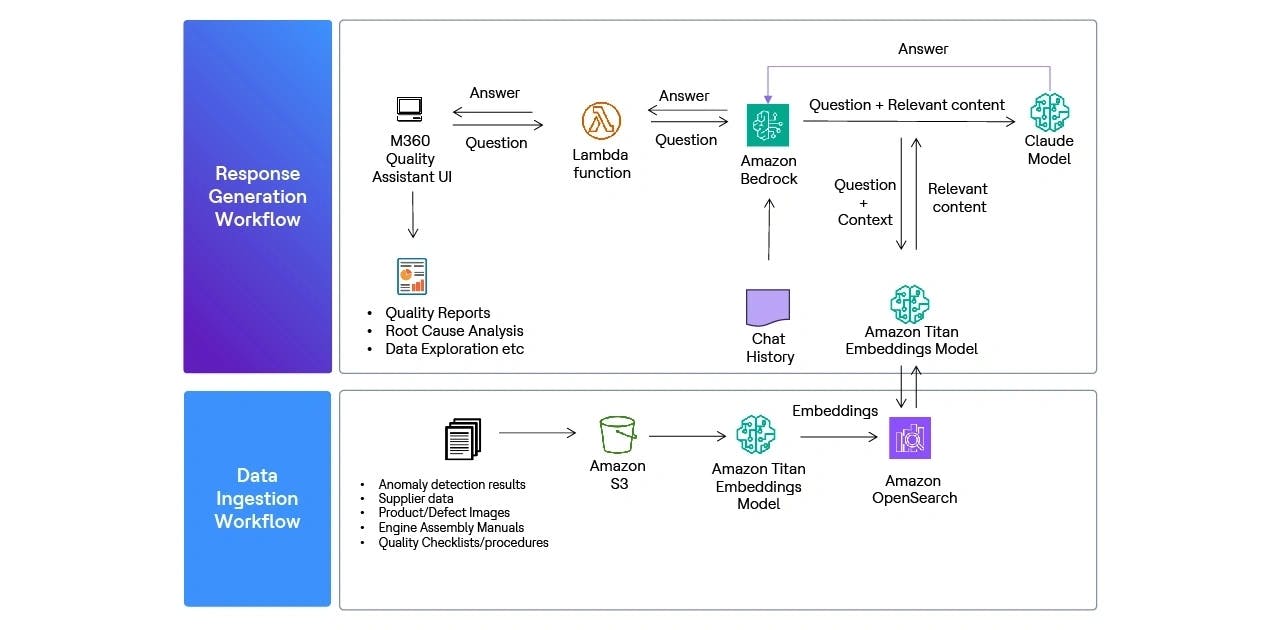

M360 Quality Assistant is a GenAI-based quality assistant that complements the ‘M360 product visual quality monitoring’ module by allowing users to diagnose quality issues, use data storytelling and accelerate dashboard authoring capabilities.

Quality assistant architecture is based on AWS GenAI services like:

- Amazon Bedrock is a fully managed service that offers a choice of foundational models from Amazon and companies like Anthropic, AI21 and Cohere through a single API

- Quality assistant uses the embeddings model from Amazon, i.e., Titan Embeddings and the Claude foundational model from Anthropic, deployed and accessed via an API on Amazon Bedrock

- To improve the accuracy and reliability of responses, quality assistant uses a retrieval-augmented generation (RAG) approach implemented with knowledge bases for Amazon Bedrock, Amazon OpenSearch to store vector embeddings and Amazon S3

Figure 4 – M360 Quality Assistant Solution Architecture

M360 suite modules

M360 offers multiple manufacturing solutions in a modular solution suite. M360 provides a flexible and cost-effective approach to implementing various use cases based on customer requirements, stage of transformation and budget. Instead of a big bang approach, customers can start with a use case, perform a quick POC by leveraging M360 accelerators to see the benefits and implement the complete solution. Iterate the process with additional use cases and implement other modules of M360 based on the customer transformation roadmap.

Figure 5 – M360 Suite Modules

Conclusion

In conclusion, integrating advanced technologies such as data platforms, knowledge graphs, cloud computing, AI, GenAI and digital twins represents a transformative leap in overcoming the multifaceted challenges of manufacturing. These technologies streamline operations and foster innovation, enabling manufacturers to respond quickly to the ever-changing market demands.

HCLTech M360 Manufacturing Suite stands at the forefront of this technological revolution, harnessing these cutting-edge tools to deliver unparalleled efficiency and precision. By leveraging such sophisticated technology, manufacturers are equipped to tackle current obstacles and future-proof their operations, ensuring sustainability and growth in the long run. As we continue to push the boundaries of what's possible within the manufacturing sector, embracing these technological advancements is not just an option but a necessity for those who wish to lead the industry into a new era of excellence.

For a detailed understanding, demonstration or implementation of this solution, please contact us at m360mfgsuite@hcltech.com

References: McKinsey, Bain and Company, IDC, PWC, MIT, Forrester, PTC, Forbes, World Economic Forum, PWC