The manufacturing industry today is on the road to significant digital transformation. This transformation is being fueled by enormous amounts of data generated from sensors, machines and human interactions that exist in typical manufacturing setups. However, extracting value from this data has been challenging due to siloed data, complex processes and a lack of skilled personnel. This has hindered the Manufacturing industry's ability to optimize operations, improve product quality and drive innovation.

So, what is the solution?

GenAI is revolutionizing the manufacturing industry by offering innovative solutions that drive business transformation. According to a report by Precedence Research Group, the global generative AI in manufacturing market size is expected to hit around $6.9 billion by 2032, registering a CAGR of 41% during the forecast period from 2023 to 2032. This creates enormous potential for problem-solving and solution enhancements for informed decision-making using diverse data outputs.

Current challenges

Before examining the potential of GenAI, it's essential to understand the key challenges that manufacturers face:

- Data quality issues: Inaccurate or incomplete data can lead to erroneous decisions and wasted resources

- Siloed data: Data is often fragmented across different systems, hindering a holistic view of operations

- Predictive challenges: Accurately forecasting demand, equipment failures, and supply chain disruptions remains a significant challenge

- Design constraints: Creating innovative products within time and budget limitations is often difficult

- Skill shortages: A lack of data scientists and AI experts can hinder the adoption of advanced technologies

- Customization and innovation: Meeting the increasing demand for customized products while fostering innovation remains challenging for many manufacturers

A catalyst for change

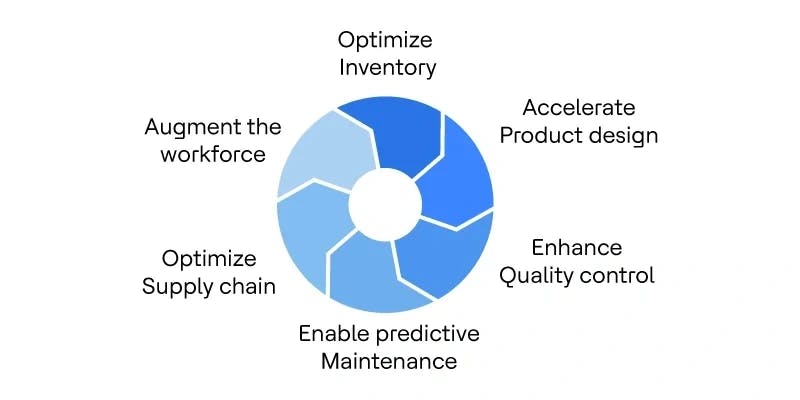

Technology has the potential to revolutionize the industry by addressing numerous challenges and driving significant improvements in the following:

- Optimizing inventory: Accurately forecast demand to avoid stockouts and excess inventory, resulting in cost savings and improved customer satisfaction

- Accelerating product design: Generate multiple design options, allowing manufacturers to explore new possibilities and bring products to market faster

- Enhancing quality control: Detect defects in real-time through image analysis, improving product quality and reducing rework

- Enabling predictive maintenance: Predict equipment failures based on historical data and sensor readings, preventing unplanned downtime and extending asset lifespan

- Optimizing supply chain: Analyze supply chain data to identify bottlenecks, optimize routes and reduce transportation costs

- Augmenting workforce: Automate routine tasks through chatbots and virtual assistants, freeing up employees for higher-value activities

Solutions offered by GenAI

GenAI tackles these challenges through various applications, significantly boosting operational efficiency, elevating quality control and driving innovation.

Process optimization

AI Algorithms analyze production data to identify inefficiencies and suggest optimizations. Gen AI-driven process optimization enables manufacturers to achieve higher output with fewer resources.

Real-time quality monitoring

AI-powered systems continuously monitor production lines, detecting defects and anomalies in real time. This proactive approach to quality control ensures consistent product standards and reduces waste due to defective products. For example, OEMs use AI for real-time quality monitoring and to enhance their manufacturing processes and product reliability.

Predictive maintenance

GenAI predicts equipment failures before they occur by analyzing historical data and identifying patterns. This allows manufacturers to perform maintenance proactively, reducing downtime and extending the lifespan of machinery.

The impact of GenAI

The impact of GenAI across industries is significant:

- Leading automotive makers can leverage GenAI to optimize production schedules based on real-time demand data. They can interact with the ChatBot based on LLMs to understand asset performance and gain insights to prevent unplanned downtimes. This would significantly improve plant performance and help in quick decision-making.

- AI-driven systems provide real-time quality monitoring and defect detection, ensuring consistent product quality and reducing waste.

- An aerospace manufacturer can utilize GenAI to predict equipment failures, preventing costly downtime and improving overall equipment effectiveness (OEE).

- GenAI can optimize supply chain performance, driving better category and space planning decisions, and deliver a personalized customer experience.

Manufacturers can realize the following benefits by including GenAI in their manufacturing setups:

- Cost savings - By reducing downtime, improving efficiency and optimizing the supply chain

- Enhanced quality - Real-time quality monitoring ensures that products meet high standards, reducing the likelihood of defects and recalls. This enhances brand reputation and satisfaction

- Increased agility - AI-driven insights allow organizations to respond quickly in time

- Innovation and customization - It fosters innovation by accelerating product design and enabling mass customization, allowing manufacturers to stay competitive

Conclusion

GenAI is a powerful catalyst for change in the manufacturing industry. It addresses critical challenges and unlocks new opportunities for efficiency, quality and innovation. By integrating GenAI into their operations, manufacturers can substantially improve and stay competitive in an increasingly dynamic market.

The future of manufacturing is bright, and GenAI is a key driver of this transformation. By harnessing the power of data and AI, manufacturers can build a more resilient, sustainable, and profitable business.

HCLTech is continuously working towards innovatively integrating GenAI in its flagship predictive analytics solution for the manufacturing industry. This integration offers capabilities such as predictive maintenance, chatbots for support, quality control and sustainable practices to users and significantly benefits manufacturing enterprises by improving productivity, reducing unplanned downtimes and making better decisions, thus improving overall production quality.