Global Supply Chains are facing significant challenges that have been exacerbated by disruptions including the Covid-19 pandemic, natural disasters, labor and talent scarcity and the complexity of products, supply chains and rapidly changing demand and supply patterns. In a recent Gartner survey, 76% of supply chain executives indicated that compared to three years ago, their company today is facing more frequent disruptions in their supply chain.

The impact is being felt across all industries through extended lead-times, limited availability of products, components and materials, reduced logistics capacity and ever-increasing operating costs. It is expected to continue for some time.

Tesla noted "….. However, we saw a continuation of manufacturing challenges related to shutdowns, global supply chain disruptions, labor shortages and logistics and other complications, which limited our ability to consistently run our factories at full capacity."

JB Hunt Transport Services reflected ongoing supply chain challenges in their Q2 Results ".... increases in: professional driver and non-driver wages and benefits, rail and truck purchased transportation expense, costs associated with inefficiencies in container utilization."

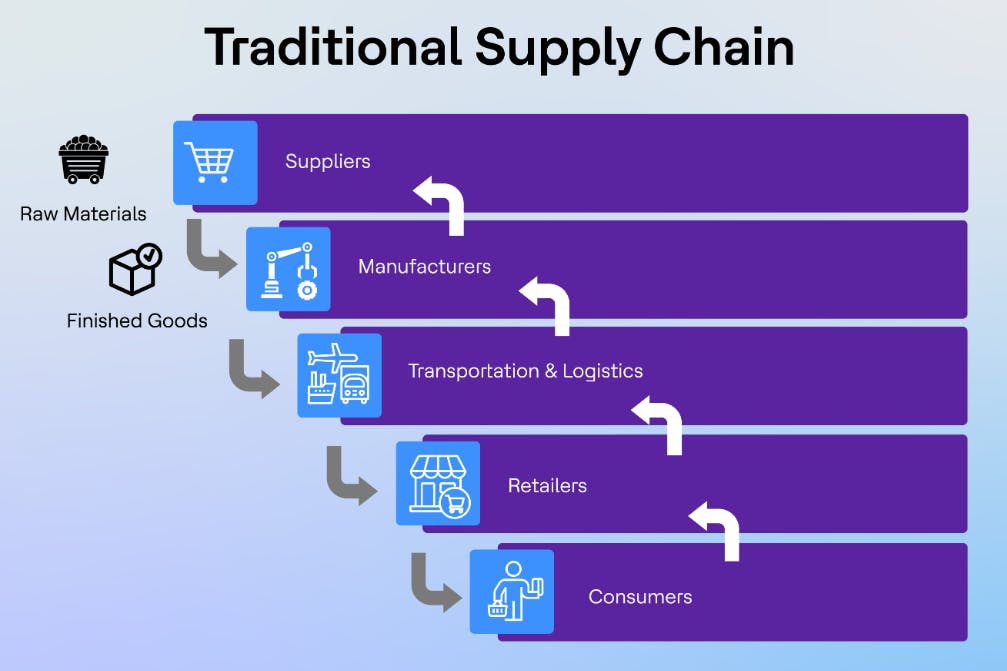

Supply chains have traditionally managed activities sequentially and were optimized utilizing Just-In-Time responsive systems and processes that minimized inventory and costs from raw materials, manufacturing, distribution, and final delivery to end customers. Organizations were able to offer vast ranges of products at competitive prices and availability with predictable lead-times.

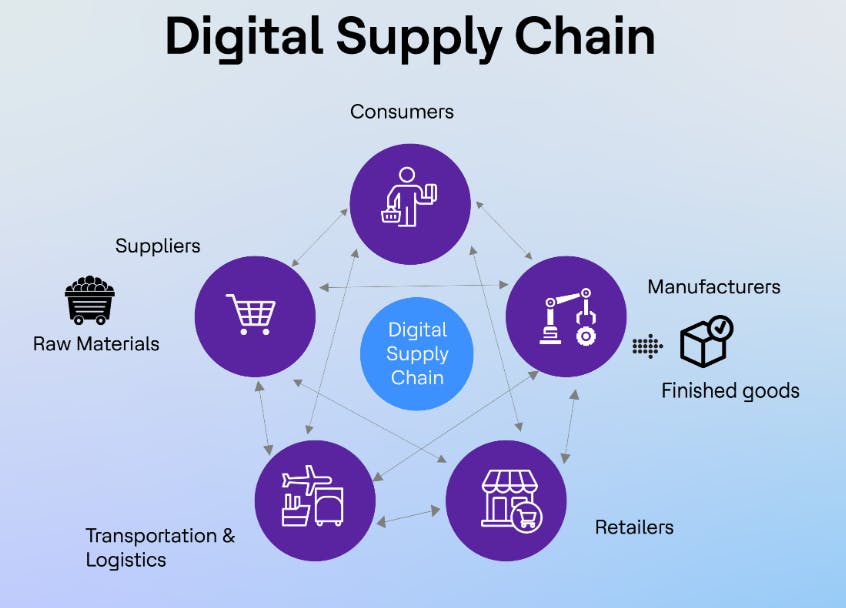

A Digital Supply Chain is needed to address these supply chain challenges and enable fast and informed responses to unexpected delays, shortages and changes in demand. It requires extensive visibility of data and insights across supply chain echelons to identify issues early so that alternate plans can be quickly developed and implemented, such as expedited freight or changes to production schedules to utilize available materials inventory and capacity to satisfy the most customers.

Digital supply chains require visibility across multiple enterprises and multiple supply chain operations. Multi-dimensional views as well as modeling and simulation improve outcomes such as delivery performance, freight optimization, minimizing last minute expediting and premium costs and cash optimization through inventory velocity.

Consumers have become accustomed to visibility of inventory availability, projected delivery dates and real-time tracking. Achieving the same experiences at an enterprise level is more complex due to interdependencies across multiple organizations and ERP systems. Visibility is often limited in certain aspects of the supply chain leading to poor planning of assets such as manufacturing or shipping. Additionally, limited visibility leads to surprises when variation occurs in those operations such as low material yields, manufacturing quality issues or transit delays adding to unpredictability for customers and supply chain managers.

A range of solutions can be adopted to improve supply chain outcomes, ranging from fast, agile tools such as dashboards that show views of forecast, orders and logistics up to leading supply chain solutions capable of simulation and modeling including real time scenario comparison, AI/ML, Control Towers and Digital Twins. These solutions can capture and assimilate data from multiple supply chain operations that enable the multi-dimensional views and advanced analytics.

Several leading Supply Chain solutions such as BlueYonder, Kinaxis, o9 Solutions, FourKites and others have enhanced their planning capabilities to create Control Towers, Digital Twins and the ability to model and implement alternative scenarios.

A good example is Mahindra & Mahindra where BlueYonder's planning platform improved inventory visibility and orchestration to enable 10% revenue growth.

A Canadian retailer utilized o9 Solutions to reliably predict consumer demand and distribute inventory across the network to effectively and efficiently fulfill that demand.

A major North American food distributor was able to better schedule their operations using FourKites improved track and trace AI driven predictive data based on location, weather, intermediate stops and more.

Global Supply Chain challenges will remain for some time and the importance of good data and digital tools will become increasingly important to manage supply chains, maintain business resilience and customer satisfaction.

Sources:

- Gartner - Six Ways Supply Chain Analytics Mitigate Business Disruptions https://www.gartner.com/en/supply-chain/trends/supply-chain-analytics-mitigate-business-disruptions

- Tesla Quarterly Update Q2 2022 (July 20, 2022) https://tesla-cdn.thron.com/static/EIUQEC_2022_Q2_Quarterly_Update_Deck_J8VLIK.pdf?xseo=&response-content-disposition=inline%3Bfilename%3D%22tsla-q2-22-update.pdf%22

- JB Hunt Transport Services J.B. Hunt Transport Services, Inc. Reports US GAAP Revenues, Net Earnings and Earnings Per Share for the Second Quarter 2022 (July 19th, 2022)https://investor.jbhunt.com/news/news-details/2022/J.B.-Hunt-Transport-Services-Inc.-Reports-US-GAAP-Revenues-Net-Earnings-and-Earnings-Per-Share-for-the-Second-Quarter-2022/default.aspx

- BlueYonder Success Story: Business Revenue Grows 10% for Mahindra & Mahindra https://blueyonder.com/knowledge-center/collateral/mahindra-mahindra-grows-business-revenue

- o9 Solutions Customer Success Story: Canadian retail leader operating across automotive, hardware, sports, and leisure. https://o9solutions.com/case-studies/general-merchandise-retailer/

- FourKites Customer Success Story: KeHe Distributors - How One Distributor Cut Manual Tasks and Boosted Revenue With Real-Time Visibility https://www.fourkites.com/wp-content/uploads/2022/04/FourKites-Case-Study-KeHE.pdf