In a world where the speed and efficiency of delivery are nearly as important as the quality of the product itself, supply chain managers are seeking innovative solutions to stay competitive. AI has emerged as a game-changer in streamlining and optimizing supply chain strategies. This article will unlock the power of AI and demonstrate how its integration can amplify returns and refine operations across various facets of the supply chain.

Predictive analytics and demand forecasting

The application of AI in predictive analytics has transformed demand forecasting from a game of educated guesses to a precise science. By analyzing historical data, market trends and consumer behavior, AI algorithms can forecast demand with remarkable accuracy. This visualization of future needs enables supply chain managers to make informed decisions, minimize excess inventory and reduce holding costs. A proactive rather than reactive approach curtails waste and consistently satisfies customer demand.

Dynamic routing and logistics optimization

AI-driven logistics platforms can deliver dynamic routing capabilities, accounting for real-time variables such as traffic conditions, weather and delivery urgencies. Traditional static routing models fall short when faced with the unexpected, whereas AI responses optimize delivery schedules and routes, reducing fuel costs and improving delivery times. These logistics advances increase customer satisfaction and support greener supply chain practices by lowering carbon emissions.

Inventory management and supply chain visibility

Efficient inventory management hinges on having the right products in the right place at the right time. AI elevates supply chain visibility by real-time tracking of goods across different stages, from manufacturing to last-mile delivery. Integrating AI helps avoid stock-outs and overstock situations, affecting the bottom line.

Furthermore, visibility across the supply chain provides insights that enable faster response to disruptions and better risk mitigation.

Predictive maintenance and asset optimization

Unplanned downtime of equipment can cause significant disruptions and financial loss. AI introduces predictive maintenance capabilities by analyzing equipment performance data to predict failures before they occur. This foresight allows for scheduled repairs and replacements during non-critical production periods. Asset optimization through AI ensures operational continuity and maximizes the lifespan of machinery.

Supplier relationship management

Strong relationships with suppliers are critical to ensuring supply chain resilience. AI solutions can analyze supplier data, track performance and predict risks, enabling supply chain managers to make more strategic partnership decisions. Enhanced selection processes based on AI insights lead to collaboration with suppliers that offer the best terms, reliability and innovation, thereby bolstering the supply chain's overall performance.

Optimized pricing and revenue management

Pricing strategies can be complex in a fluctuating market. AI algorithms can examine an extensive set of variables to suggest optimal pricing for products and services. By doing so, supply chains can react instantly to market changes, whether it results in increasing demand or disposing of surplus inventory. AI-enhanced pricing strategies boost sales and contribute significantly to revenue growth.

Ethical and sustainable supply chain practices

Consumer demand for ethical and sustainable business practices has never been higher. AI can audit supply chains for compliance with regulations and industry standards, ensuring that ethical practices are upheld at every stage. By tapping into the abilities of AI to monitor and report on sustainability metrics, companies can better manage their environmental impact and respond to customer expectations for corporate responsibility.

The market imperative

Today's market requires more than efficiency; it demands agility, foresight and the ability to pivot as conditions change. With customer expectations soaring and market demands constantly shifting, managing a supply chain has become multifaceted and strategically critical. It no longer suffices to manage a back-end process. Supply chains now need to be leveraged as a competitive advantage.

AI is at the vanguard of this transformation. It's not just reducing costs — it's driving forward-thinking companies towards more innovative, faster and more ethical supply chains that can adapt to the future, whatever it may hold. By harnessing the power of AI, supply chain managers can unlock unprecedented returns and effectively meet the challenges of today's complex market dynamics.

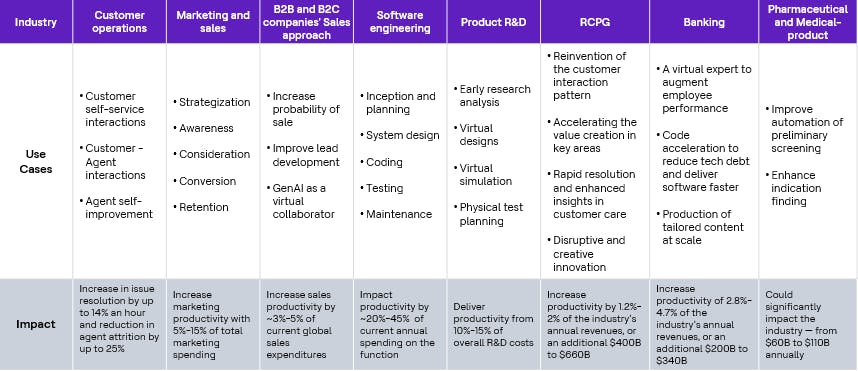

McKinsey & Company highlights some key use cases below:

McKinsey's findings indicate that 61% of manufacturing executives have observed reduced costs, while 53% have seen boosted revenues following the implementation of AI in their supply chains. Additionally, over a third of respondents anticipate a total revenue increase of over 5%.

For supply chain managers, the time to act is now. Integrating AI into supply chain operations is not a passing trend. It is the foundational element of next-generation supply chains — resilient, responsive and resonant with stakeholder values. Commitment to exploring AI solutions within strategies will ensure that processes become more agile, with lower risks, increased customer satisfaction and maximized returns. In this era of AI, those who adopt and adapt will oversee redefining the landscape of global supply chains.