Our client, a leading American multinational company with diverse operations in building automation, security and fire safety, sought eco-friendly solutions to safeguard delicate products while minimizing environmental impact. Using alternative materials and leveraging eco-design principles, this initiative supported the client's commitment to support sustainability goals, aiming for carbon neutrality by 2035 and aligning with evolving industry standards for carbon footprint reduction. Despite notable achievements, challenges emerged, including a marginal increase in packing cycle time, packaging supplier negotiations, concern regarding dust cover retention and navigating marketing approval processes.

savings in manufacturing stage of lifecycle

reduction in carbon emission

annual cost savings by changing packaging type

The Challenge

Transitioning from traditional packaging materials to eco-friendly materials to meet their sustainability goals

Amidst a regulatory shift where companies focus more on sustainability, our client aligns with this trend. With a legacy of over a century, our client has been a pioneer in environmental responsibility through technology solutions that mitigate greenhouse gas emissions, increase energy efficiency and drive efficiency across its operations and those of its customers.

As part of this commitment, our client recognized the imperative to shift from –

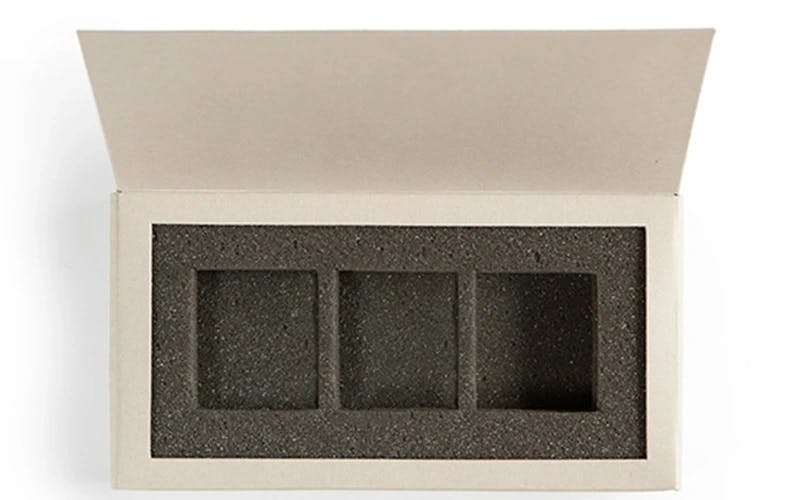

- Plastic clamshell to paper-based monocarton

- EPS foam blocks to paper-based corrugated insert

Grounded in meticulous evaluation and benchmarking of various materials, this decision underscored the company's commitment to sustainable practices.

However, there were some challenges, including meeting specific sustainability standards and regulations, ensuring a seamless transition in design, managing a marginal increase in packing cycle time, negotiating with packaging suppliers, addressing concerns regarding dust cover retention, and navigating marketing approval processes.

The Objective

Proposing tailored eco-design solutions by minimising scope 1 and scope 2 emissions through cradle-to-gate assessment

Our team conducted a thorough analysis of regulations in product manufacturing locations and target markets. Their objective was to propose eco-design solutions that integrate Extended Producer Responsibility (EPR) commitments and shift from plastic to paper to reduce waste. Moreover, the team focused on minimizing scope 1 and scope 2 emissions through cradle-to-gate assessment in packaging design. The recommendations included selecting materials for protective packaging and dust covers that align with green principles while maintaining cost efficiency.

The Solution

Creating sustainable packaging solutions for client success

The client sought greener, more sustainable packaging solutions, prompting our team of designers to explore alternatives for their plastic clamshell packaging and EPS foam blocks. We proposed various options, including eco-friendly materials such as honeycomb, molded pulp, mushroom, seaweed and recycled PET. However, some of these options were rejected in the later stage as the primary concern was to provide dust covers and cushioning for their product during transit.

We evaluated the feasibility and impact of each option with cost and life cycle analysis before presenting the final designs to the client for approval.

We then proceeded to the testing and prototyping stage to verify the new packaging's ability to withstand the stress and strain of transportation and handling. Our team conducted a range of transit tests, such as drop tests, providing feedback and suggestions for improvement to the client.

Upon successful testing, we helped the client launch their new packaging in the market, ensuring a smooth and seamless transition with minimal disruption and maximum efficiency. Additionally, we offered continuous support and guidance to help them maintain and optimize their sustainable packaging practices.

The Impact

Fostering environmentally conscious solutions while enhancing operational efficiency

By implementing a comprehensive transformation strategy at scale without service disruption, we empowered the client to achieve remarkable outcomes.

Through a strategic transition from plastic clamshell to paper-based monocarton, the client realized a significant annual cost saving of ten-percent and a substantial 26% reduction in carbon emissions. Furthermore, our transition from EPS foam blocks to paper-based corrugated insert yielded an impressive annual cost saving of 40% and orchestrated a notable 42% reduction in carbon emissions.

By optimizing material usage, streamlining production processes and prioritizing consumer preferences for eco-friendly products, we achieved cost savings and bolstered overall profitability.

Our transformative approach not only helped the client comply with packaging regulations in accordance with global market trends, but it also enhanced customer satisfaction, reaffirming our commitment to innovation, cost-effectiveness and ecological stewardship.