Who would have thought that an aircraft could fly into the eye of a hurricane? It happened for the first time on July 27th, 1943, when Joseph B. Duckworth, an instrument flight instructor, and a US Army Air Forces Lt. Col., did it on a dare. When Duckworth safely returned to base, the meteorologist there immediately requested to be a passenger on a second flight into the same hurricane. As unlikely as it sounds, the aircraft weathered the storm twice on two consecutive flights.

Such is the case of the aerospace and defense (A&D) industry. The A&D industry has always had to weather adversity, be it from war, unrest, oil embargos, emerging competition, supply chain disruptions, manpower shortages, financial downturns or global pandemics. One could say nothing has changed in some respects with unforeseen events always lurking just beyond the horizon. In other respects though, a lot has changed.

Just as flight instruments allow an aircraft to navigate inclement weather, technology provides A&D companies with better preparedness for what lies beyond the horizon. Artificial intelligence (AI) provides predictive foresight into maintenance and supply chain concerns. Digital thread simulation enhances manufacturing efficiency and customer satisfaction. One would be hard-pressed to find an A&D company that didn’t have innovation or digital transformation as a strategic goal.

One major focus of transformation in A&D is the digital thread. A major benefit of digital thread is the ability to simulate product performance, manufacturability, maintenance and mission readiness long before manufacturing begins. The digital thread is, without question, the new norm for A&D. Therefore, for a company, knowing how to navigate the digital thread transformational journey is a must. Today, it spans across enterprise resource planning (ERP), product lifecycle management (PLM), manufacturing execution solutions/systems (MES) and manufacturing operations management (MOM).

The ERP decision is predominately SAP in A&D and the PLM solution will normally be one (or more) of the big three—Siemens, Dassault or PTC. This leaves us with the MES/MOM selection. There are many choices here such as Apriso, OpCenter, Solumina, ME/Mii, DMC and so on. However, the solution gaining momentum in A&D is SAP S/4HANA Manufacturing for production engineering and operations (PEO). Let’s find out why.

SAP PEO on the rise

When looking at A&D from the outside in, the industry is engineering-centric and resource-dependent. PEO provides a new approach, allowing the engineering centricity of PLM and the resource dependency of ERP to work together as one unified solution. It doesn’t matter if the engineering source is Siemens, Dassault or PTC, nor does it matter if engineering is providing just an engineering bill of materials (EBOM) or a complete bill of process. The production engineering side of PEO is designed to accommodate any of the big three PLM sources (with any level of bill-of-process detail), provide enterprise resource context and execute on the shop floor via the production operations side of PEO. There is no longer a need for a standalone MES/MOM add-on.

What SAP has done is to build manufacturing execution and operations management capability directly within the S/4HANA digital core, thereby, eliminating the need for an additional MES/MOM solution. I will summarize benefits later but it is worth pointing out here that eliminating the need for a standalone MES/MOM solution, in turn, eliminates the need for multi-million dollar custom ERP to MES/MOM interfaces (members of the SAP A&D industry advisory council verbally expressed annual savings estimates of between 1.5 and 2 million dollars).

The workings of SAP PEO

So, how does PEO work?

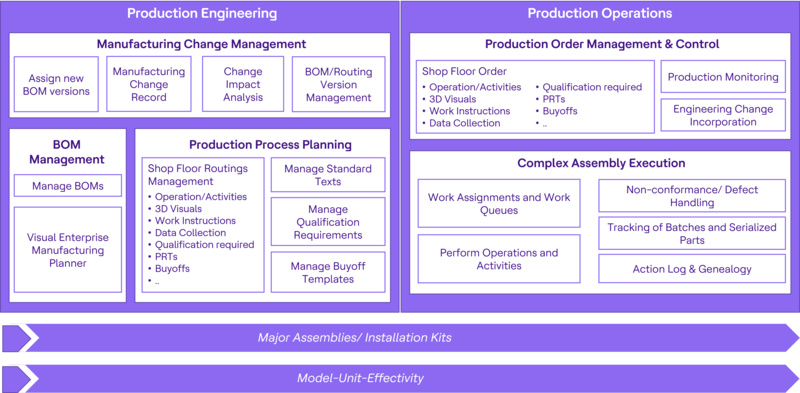

Through its production integration portal, PEO can receive any level of PLM bill of process detail. Anything from EBOM, MBOM, operations structure, model-based definitions, product manufacturing information, and supporting documents are included in the details that the portal can take in. The engineering side of PEO will perform a change impact analysis, evaluating master data and the work in process. It can also augment the bill of the process with the required enterprise resource context. And, if required, it can also provide an additional bill of process authoring capabilities, including production manufacturing information (PMI) based data collection, work instruction, hyperlinks, and multimedia, to name a few examples.

In summation, the engineering side of PEO can receive anything from an EBOM skeleton to a fully-fledged bill of process, perform a change impact analysis, and augment the bill of the process with additional enterprise resource context.

Figure 1: SAP PEO capabilities

On the production operations side of PEO, HTML5-compliant work execution can be carried out on any device. The functionality of any modern MES/MOM is included—3D model-based work instructions, work precedence, traceability, data collection, skill validation, genealogy, as-built history, electronic signature, and so on. Moreover, because PEO is built in the SAP S/4HANA digital core, PEO also makes use of SAP Quality Management for non-conformance, corrective action, and maintenance review board (MRB) processing. For an MES/MOM solution, PEO also has unprecedented visibility into the supply chain and resource availability as a result of residing within the same SAP S/4HANA digital core.

The SAP PEO advantage

Additional benefits include:

- A single integrated management platform for planning, scheduling and executing production operations, streamlining the production process and increasing overall efficiency

- Effective management of production resources such as machinery, equipment and labor, optimizing resource utilization

- Quality control functionalities that can help identify and address production defects early in the process, reducing rework costs

- Enhanced supply chain visibility by providing real-time updates on production status, inventory levels and delivery schedules

- Linking model-based definition to business outcomes

- Order split that takes into account financial and contractual compliance

- Real-time inventory, supply chain, and financial updates with one-click options for each shop floor

- Seamless integration to project systems/program management

- Comprehensive as-built history that spans engineering, manufacturing and the overall supply chain

- Variant configuration connecting engineering, routings, work instructions, shop orders and the supply chain seamlessly to customer purchase order option selections

- Extended maintenance, repair and overhaul/operations (MRO) with predictive maintenance

- The ability to leverage engineering-sourced product manufacturing information (PMI) for shop floor operations

- Design handover, process definition, and production execution processing

- Real-time production order management and control

- Project structure synchronization with major assembly manufacturing BOM

- An action handler framework for PEO to be extended with additional capability; as it is built on top of ABAP code and HTML5, customers and/or their system integrator (SI) partners such as HCLTech, can extend PEO without having to revert to the vendor (SAP, Siemens, Dassault)

Ready for Prime Time

A&D companies can now utilize SAP PEO to better manage and support their complex build processes that result from changes in design, manufacturing bills of materials, routing processes, work instructions, and production orders. While PEO comes as an integral part of S/4HANA manufacturing, for companies that have not yet migrated to SAP S/4HANA, SAP also provides the capability to deploy “Sidecar PEO” where PEO runs concurrently with the traditional SAP ERP/ECC.

PEO has reached a high level of product maturity with a solid production engineering and production operations core defined through an SAP Customer Engagement Initiative, the PEO Early Adopters Group, and through guidance from the SAP A&D Industry Advisory Council. Each customer may however have specific requirements not covered by core functionality.

Why HCLTech?

To help customers fill functional gaps and accelerate PEO deployment, HCLTech has created a preconfigured PEO template. The template includes usability enhancements such as Responsibility Management, Automatic Routing Selection, and Default Values as well as reports that address A&D industry nuances. Moreover, HCLTech provides Industry 4.0 expertise, enabling PEO plant floor connectivity. As the industry leader in A&D maintenance, repair and overhaul with iMRO, HCLTech is perfectly positioned to satisfy original equipment manufacturers that also provide re-manufacturing/MRO services–manufacturing and MRO all on the same S/4HANA digital core.

To know more about our PEO capabilities, please get in touch with michael.edelen@hcltech.com.

ihttps://blogs.sap.com/2019/11/22/s-4hana-manufacturing-for-production-engineering-and-operations/